Single Check Valve Qrc

The Stainless Steel QRC Single Check Valve is a one-way automatic shutoff valve located in the socket, primarily designed for pneumatic tool lines. It facilitates the connection of air piping in factories and air tools with hoses. Both the socket and plug are available for threaded and hose connections.

The Quick Release Coupling (Single Check Valve) is ideal for systems requiring one-sided flow and where flow sealing is essential. It provides a leak-proof connection without the need for mechanical tools, achieved simply by pressing the plug into the socket.

The Quick Disconnect Coupling (Single Check Valve) includes an unvalved plug designed to release pressurized air into the atmosphere, ensuring safe and efficient operation.

Specification

Type: Single Shut-Off

Material: Brass, Stainless Steel, or Plastic

Application: Hydraulic, Pneumatic

Temperature: 40* C TO 300* C

Max Pressure: 3000 PSI

Seal Type: Nitrile, Viton

Connection Type: Female-to-Female, Female-to-Male, Male-to-Male, Male-to-Hose Barb.

Size Range: 1″ to 4″

Quick Release Coupling Types

PRECAUTION:

- Fluid flow direction is from coupler to adaptor and not the vice-versa.

- Can not be connected / disconnected under pressure.

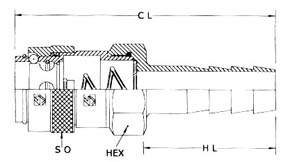

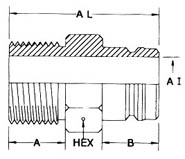

| N M n l. SIZE | AL | AI | HI | A | B | Coupled Length | CL | SO | HL | HeX. | Wrk. Prss. PSI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4″ | 50 | 06 | 04 | 28 | 18 | 112 | 79 | 25 | 30 | 22 | 1500 |

| 3/8″ | 60 | 09 | 07 | 34 | 18 | 133 | 94 | 30 | 48 | 25 | 1500 |

| 1/2″ | 74 | 11 | 09 | 45 | 20 | 158 | 108 | 33 | 59 | 28 | 750 |

| 3/4″ | 89 | 17 | 16 | 55 | 22 | 185 | 123 | 41 | 70 | 35 | 750 |

| 1″ | 107 | 23 | 22 | 70 | 23 | 220 | 143 | 48 | 87 | 42 | 500 |

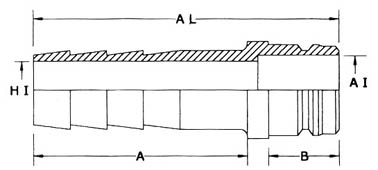

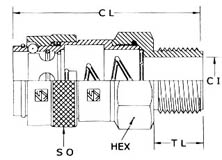

| THRDS. SIZE | A | B | AL | AI | BHex. | Coupled Length | CL | CI | SO | HeX. | TL | Wrk. Prss. PSI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4″ | 12 | 18 | 37 | 06 | 15 | 077 | 64 | 07 | 25 | 22 | 12 | 1500 |

| 3/8″ | 14 | 18 | 40 | 09 | 17 | 086 | 73 | 09 | 30 | 25 | 13 | 1500 |

| 1/2″ | 16 | 20 | 52 | 11 | 22 | 094 | 79 | 14 | 33 | 28 | 16 | 750 |

| 3/4″ | 18 | 22 | 58 | 17 | 28 | 101 | 85 | 18 | 41 | 35 | 18 | 750 |

| 1″ | 23 | 23 | 65 | 23 | 35 | 118 | 98 | 23 | 48 | 41 | 23 | 500 |

Properties & Physical Features

These couplings are manufactured in various metals, with different end connections like, Female / Male Threaded, Hose Shank, Flange End, Socket / Butt Weld End.

METALS OF ASSEMBLY

| BODY | BALLS | SPRINGS | VALVES |

|---|---|---|---|

| Brass | SS.304 | SS.304 | Brass |

| SS.304 | SS.304 | SS.304 | SS.304 |

| SS.316 | SS.316 | SS.316 | SS.316 |

| Carbon Steel | Carbon Steel | SS. | Carbon Steel |

SEAL MATERIAL

| RUBBER | OPERATING TEMPERATURE | RECOMMENDED APPLICATION |

|---|---|---|

| NITRILE | -20°C TO + 90°C | OIL RESISTANT |

| NEOPRENE | -20°C TO + 100°C | FREON / OZONE RESISTANT |

| EPDM | -20°C TO + 120°C | STEAM RESISTANT |

| SILICON | -20°C TO + 180°C | DRY HEAT |

| VITON | -20°C TO + 220°C | HEAT AND / OR CHEMICAL |

| TEFLON | -40°C TO + 260°C | HIGH TEMPERATURE |

QUALITY CONTORL

Each AVLOK Coupling manufactured goes through stringent quality control, right from the procurement of raw material upto final stage.

PRECAUTION :

- Avoid connecting or disconnecting a coupling under pressure.

- Residual pressure in a coupling may make it difficult to connect. In such a case, do not strike the valve end to depressurize it.

- Improper selection of seal rubber may cause leakage.

- Dust or flaws in the seal may cause leakage.

- Improper selection or improper use of the products can cause personal injury and property damage.

Enquiry

If you have any query related to this product please contact us at +912222821251 or reach to us through email at info@avlok.com. Our experts would guide you the same and inform regarding other various metals suitable for your applications.

We export worldwide